What’s Next: Liquid Printing

3D printing, although becoming increasingly popular, still has some limitations. Unlike injection molding or casting, it has only found its home in small-scale production and generally suffers from a relatively slow print speed.

3D printing, although becoming increasingly popular, still has some limitations. Unlike injection molding or casting, it has only found its home in small-scale production and generally suffers from a relatively slow print speed.

Researchers at MIT are experimenting with a new 3D process called rapid liquid printing. Designed to tackle large-scale production, it doesn’t rely on specialized or prototype materials.

How it works

How it works

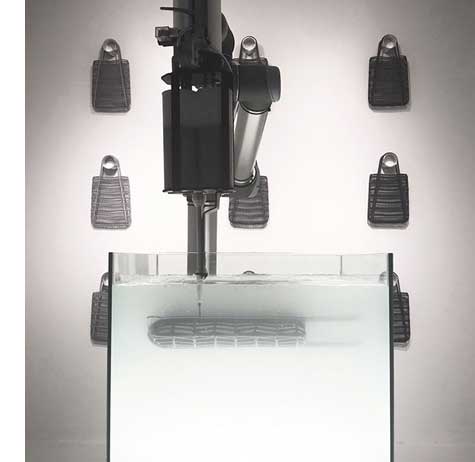

While 3D printing relies on layer-by-layer creation, rapid liquid printing “draws” an object by injecting its printing material (rubber, foam, or plastic) into a thick, transparent liquid gel suspension. Instead of building up layers of material, the material is excreted from the printhead and into the gel. Because the gel material suspends the printed object, it allows for more printing accuracy and less material waste. The resulting printed object will have better structural integrity than if it was laid down as a series of layers – essential if it needs to bear weight or other stresses.

Some printing materials are designed to harden by a chemical reaction when coming into contact with the gel, so there is no need for light or changes in temperature. The printed object can be removed without additional curing.

The printhead is attached to a robotic arm, allowing it to approach the object from multiple angles. Although there are currently only a few relatively small versions of liquid printers, there are no limits to scale. With a large enough tank, the process can create objects of any size.

The suspension gel is basic and is similar to hair gel or hand sanitizer. It has two essential functions. The first is that it can suspend objects, so they are not adversely affected by gravity. The second is that the gel self-heals after the nozzle passes through, allowing the print heads to continuously move and print within the gel and not create tunnels or cavities which would fill up with excess printed material that must be dealt with later. The gel can be mixed to a specified density to accommodate the weight and bulk of the printed material.

How it might be used

Customization is the key. Liquid printing could also open up new avenues for production in the furniture, automotive, and aerospace industries, where fast, large-scale manufacturing is essential.

Rapid liquid printing is still in the research phase, but MIT researchers are planning for larger-scale liquid printers using other printing materials.

Return to the Tech Trends Newsletter