UNUSUAL PRINTERS

What do you use your printer for? Probably the same thing most everybody else does – print documents and photographs. While there is a vast selection of printers to choose from, with all levels of bells and whistles, they will ultimately serve the same purposes.

But not all printers are typical. In previous newsletters, we’ve spoken about 3D and 4D printers. As you’ll see, several unusual printers leverage 3D printing technology for highly specified purposes.

Concrete Printer

If two things don’t sound like they go together, it’s concrete and printing. As you might expect, concrete printing has evolved because 3D printing technology has made it possible.

Using a method called “contour crafting,” the concrete printer outputs precise layers of concrete as it compiles the finished object. Originally used to create concrete panels for construction purposes, in 2017, some manufacturers have begun using concrete printers to “print” entire dwellings.

Bioprinter

If you can print a house, then why not a heart? Using 3D printing combined with inkjet technology, scientists can print thousands of cells per second to form a 3-dimensional biological structure. The technology prints layers of cells to create the desired object, such as a blood vessel. Most bioprinters also output a dissolvable gel to support and protect cells during printing. Today, bioprinters are still in the experimental stage. But they will, someday, be able to “print” life-saving things.

Nanoparticle Ink Printer

To replace the vacuum tool technology they previously had to rely on, a solar panel manufacturer has created a printer that prints the thin, solar film panels using nanoparticle ink. This highly specialized ink contains silver nanoparticles that conduct electricity while remaining flexible and retaining its adhesive properties. The large, costly printer can print over 100 feet of solar film per minute.

Glass Printer

That glass you just drank out of might not be made the way you think it was. Glass printers use ceramic “glass” ink, which contains nanoparticles of quartz glass with a tiny amount of liquid polymer. The object is cured at specific points by ultraviolet light using stereolithography during the printing process. The cured portions harden while the rest remain liquid, essentially building up the shape of the object one layer at a time. The object is then washed in a solvent bath and heated to form a fully fused and strong structure.

It is beneficial to glass manufacturers who can use it to print tempered and laminated glass. Multiple colors can print simultaneously, saving a tremendous amount of time during manufacturing and allowing for almost any design and pattern.

The printers we’ve mentioned have all served useful purposes. But some are just downright silly.

Waterfall Printer

If a printer can jet out ink, then why not water? Care to create a waterfall in your office lobby? Several frustrated inventors have used basic print technology to create rather dramatic water shows.

The printer heads are suspended upside down above a pool and eject the water according to specific preprogrammed patterns, creating a falling wall of water that takes on the shape of a flattened object, or even text, as the water falls from the print head to the pool. Often called aqua graphics or digital water curtains, you need to look quick, though, because the “printed” water only retains its shape for a second.

RITI Printer

Ink is expensive. When you consider how much you pay for a small print cartridge, it’s one of the most expensive liquids. An artist and designer in Korea have come up with a way to utilize coffee and tea dregs in place of ink.

The is one catch, however. It does not operate on its own. The RITI printer requires a bit of manual operation because users have to fill the cartridge with the dregs of their choice and a bit of water. They have to move the cartridge back and forth to mimic the cartridge movement of regular printers. While it might not print as fast as, or quality on a par with, an inkjet printer, it is incredibly eco-friendly.

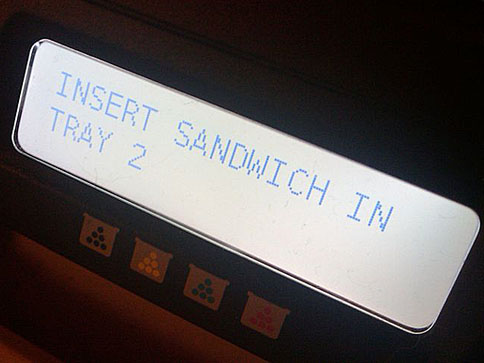

Toaster Printer

If you’re going to use your leftover coffee to print something, why not use your toast? As the name implies, toaster printers use heating elements to “print” on toast. The first toaster printers could only burn 12ppi (pixels per inch). Here’s hoping they have since improved. Nobody should have to tolerate pixelated toast.

Return to the Tech Trends Newsletter