Is Your Project in a Bind?

Today’s multifunction printers can do many things, including binding printed pages into a finished product. While there are multiple ways to bind your documents into a finished product, including spiral or wire-o binding, the two most common are saddle stitching and perfect binding. Undoubtedly, you’ve encountered both of them before.

Today’s multifunction printers can do many things, including binding printed pages into a finished product. While there are multiple ways to bind your documents into a finished product, including spiral or wire-o binding, the two most common are saddle stitching and perfect binding. Undoubtedly, you’ve encountered both of them before.

SADDLE STITCHING

Saddle stitching is a binding method that holds folded sheets of paper with wire staples passing through the crease. Sheets print at twice the width of the final product with one on the left, one on the right, and both sides. If the finished product is 8.5 inches by 11 inches, each printed page will be 11 inches by 17 inches before getting folded and stapled.

Once printed, the collated sheets go over a piece of equipment that resembles a saddle (hence the term “saddle stitching”), and the staples are passed from the outer spine and fastened at the center. Saddle stitching is the most common bindery used for small booklets, catalogs, or magazines. Large items are incapable of lying flat across the saddle and may also be too thick to staple.

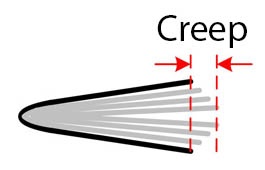

One drawback to saddle stitching is the more pages you add, the more you will notice that the inside (or middle) pages stick out further than the outside pages after stitching. This problem is called “creep” and happens because the paper along the folded edge takes up space and pushes out the inside pages. The finished booklet will then need trimming to look decent.

PERFECT BINDING

Perfect binding is what we see used most often to bind larger items such as books together. Instead of staples, the pages are glued together at the spine, and the cover is wrapped around them.

Perfect binding is often a slower and more expensive process than saddle stitching, but it results in a very professional-looking finished piece with a spine that can also be printed with text and/or graphics. This type of bindery is durable, and it allows even very thick publications to lie flat when closed (unlike saddle stitching).

Regardless of which type of binding you decide to use for your finished product, it’s important to consider this during the design phase. Saddle stitching, especially, will require you to design around the fold that happens as part of the stitching process. You don’t want to end up with any print buried too deep in the fold of the booklet’s spine or too near an edge that may be trimmed. Perfect binding does not require as much space around the inside edge, and therefor is less of a design constraint.

Return to the Tech Trends Newsletter