Manapság a vállalkozásoknak rugalmasnak és alkalmazkodóképesnek kell lenniük. Ez különösen igaz olyan szektorokban, mint az online kaszinóipar. Az új technológiák bevezetése, ahogyan azt az ivibet szerencsejáték-platform sikeresen meg is tette, versenyelőnyt jelenthet a vállalkozások számára. Az ivibet áttekintése, amely a https://kaszino-world.com/ivibet/ oldalon található, megmutatja, hogy az első osztályú digitális megoldások elfogadása hogyan forradalmasíthatja az üzleti tevékenységet.

Hasonlóan hozzájuk, a Capital Business Systems célja, hogy magas színvonalú irodai technológiai megoldásokat nyújtson Önnek, amelyek az Ön konkrét igényeire vannak szabva. A legújabb nyomtatókkal, szkennerekkel és IT-szolgáltatásokkal felszerelve lehetővé tesszük vállalkozásának, hogy nagy lépéseket tegyen nemcsak céljainak elérésében, hanem azok túllépésében is.

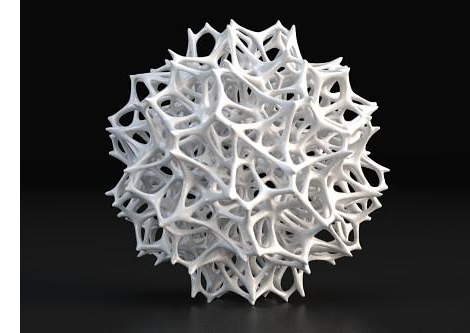

5D Printing…….yeah, it’s a thing.

But now, we have 5-D printing. Sort of.

5-D printing is not the addition of an additional dimension. Which is good, because then we’d have to rewrite every physics book in existence. A more accurate name for 5-D printing might be 5-axis printing.

Let’s start by looking at a few basics of 3-D object creation.

One way of creating a 3-D object is by employing a subtractive method of creation. Think of a stone carver. They subtract the material (the stone) as necessary and are left with their sculpted object. Or a woodworker using a lathe to create a spindle from a block of wood.

On the other hand, 3D-printing, along with 4-D and now 5-D printing, are based on additive printing. Layers of a substance (usually plastic) are simply added together by printing them out one on top of another to form an object.

The concept of 5-D printing begins with 3-D additive printing, and is augmented by the addition of two axes which come via a movable printer bed that rocks back and forth as required. When 3-D printer heads can approach the object from any angle, as opposed to just from above as with all standard 3-D printers, far more printing possibilities are available – and not just in terms of the overall shape of a finished object.

5-D printing can also eliminate the sometimes-necessary task of having to “clean-up” an object after it’s been printed. In certain cases, objects printed with a basic 3-D printer must be printed with support pieces or other appendages left in place due to the top-down only access of a 3-D printer head. Because 5-D printer heads approach the object from multiple angles, those appendages need not be printed in the first place, saving time and material.

In January of 2018, one of the first 5-D, commercially available printers won a “Best of Innovation” award at the massive Consumer Electronics Show in Las Vegas – a sure sign that 5-D printing will be part of our lives someday, whether we realize it or not.

Return to the Tech Trends Newsletter